Rapid publication

Boulanger has installed the independent independent Locus Robotics (AMRS) robots (AMRS) to capture it in the Hénin-Beaumont warehouse, in northern France. The facility runs a wide range of consumer electronics and home appliances, and distributing shares to more than 200 stores throughout the country. Managers say that publishing has strengthened the efficiency of the workforce, as Warehouse partners work alongside Amrs – Androids carry out heavy lifting and travel through the corridors, which reduces the amount of time that colleagues spend on these tasks, and therefore, fulfillment of speed.

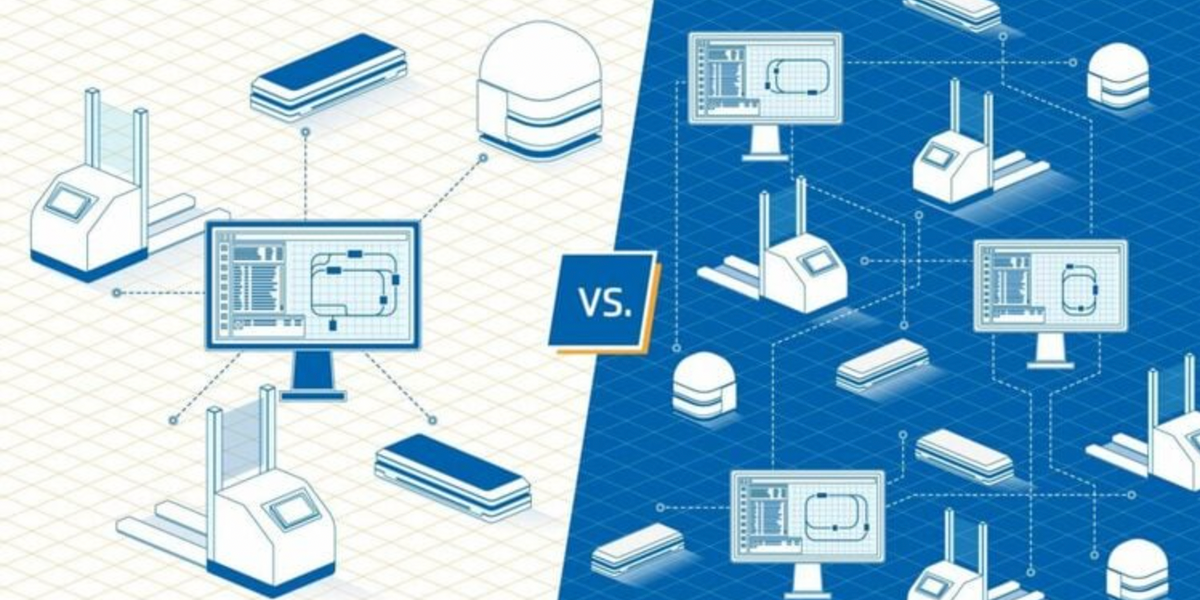

AMRS, which works on the AI’s Locusone software platform, has been installed in less than four months and smoothly integrating with Boulanger (WMS) warehouse management system and current material processing equipment-as it guarantees smooth operations without disrupting the applicable workflow, according to both companies.

Rapid installation was followed by quick results: within six weeks of living with the system, Bollandger doubled its production.

Solid results

The ability to expand the solution was a blessing for Boulanger’s business as well: Locus enables the response to the height of 30 % at work by quickly adding AMRS to the fleet. Locus Robotics’ Robots-SA-Service (RAS) model makes it possible, allowing companies to be measured without the burden of large capital investments.

The results speak for itself: within six weeks, productivity in the Hénin-Beaumont facility increased from 120 units that are treated per hour to more than 250. In addition, the facility processed approximately 9 million units in less than a year, “showing exceptional efficiency”, according to both companies.

“The rapid shift of Polangers explains how flexible automation can revolutionize the fulfillment of loyalty,” said Dennis Nizuda, chief trading official at Locus Robotics, in the statement. “By integrating Locusone, Boulanger has gained the ability to expand, efficient and light movement needed to meet the increasing customer expectations. This publish enhances our commitment to supporting the advanced logistical scene in France with smart and developed automation solutions.”

Now the partners turn their attention to new applications.

“We are exploring additional workflow tasks, we can automate under Locusone,” Hinen said in the statement. “This fitness allows us to adjust the capacity dynamically, eliminating the need to invest in unarmed solid automation – critical and we celebrate the seventieth anniversary of our founding with a major sales campaign.”