Tradlinx provides 99 % resolution by tracking goods, not containers, and converting the chain of supply chain into a competitive feature

The global supply chain is in a state of permanent turmoil. The geopolitical struggle, economic volatility, and an indiscriminate demand made an accurate prediction and the necessities of survival in actual time. One in three of the supply chain leaders now occupies the predictive management as a maximum priority, while half of their half focuses on technology for vision in actual time.

In this high -risk environment, Data accuracy The final scale has become. However, the data on which most companies depend is mainly broken. Logistics company, Tradlinx, change the standard. with 99 % accuracy rate Its health has been validated by global leaders such as Samsung, Canon and Philips, Tradlinx proves that superior data turns uncertainty into a decisive feature.

Form turning: from one point data to huge data intelligence

Poor traditional shipping tracking is not the container number itself, however Exclusive accreditation Its one source of the truth. When tracking systems only depend on this data point, failure is guaranteed. During the transition, when the goods are transferred to a new container, the original number becomes old, the course of the data disappears, and the vision disappears. This is the critical blind spot that creates expensive delays and operational chaos.

Tradlinx understood that this solution requires a much more sophisticated approach. Over the past decade, the company has developed and has been built Large light dataCollect and refine More than 200 million points of international import/export data every month.

This process that relies on intelligence begins using two main pieces of information as reference points: Shipping Bill (B/L)Which is a fixed anchor of the entire shipment, and Container numberAnd that determines the current financial location of the shipment.

When a container or ship change occurs, the huge data warehouse works in Tradlinx as a connective tissue. It refers to billions of data points to connect the old container logically new container under the same B/L, ensuring that the data course remains unnecessary. The result is a smooth and comprehensive vision to a tip that is still intact, even when the containers are replaced, ships change, or interior goods move.

This strong mixture of tracking B/L is processed, container monitoring, and huge data analyzes by a special engine of 3 stages:

1. The rubble: Core B/L containing container information, actual time AIS, global port data, and huge historical logistical database of Tradlinx.

2. Recruitment: A hybrid system of advanced algorithms and Humanitarian team from experts It accurately cleans the data and resolving the conflicts – such as linking the shipment with a new container number after transportation – and ensuring integrity.

3. Delivery: The system provides a unified and reliable information with updates per hour –12x faster From competitors – predictive visions, proactive warning of potential delays so that users can act before A problem occurs.

The result is operational Data accuracy by 99.5 %. In direct comparisons, Tradlinx accuracy is 93 % – top 38 ° C higher From the average industry 55 %.

The bottom line: From accuracy to the return on investment

This level of accuracy provides a measurable effect.

Logistics Achieved a 50 % reduction In manual tracking tasks and $ 60,000 in annual cost savings.

-Logistics manager in Ecclesiastical I mentioned that Tradlinx “reduced our shipping management time from hours to Less than one minute per b/l“

-Lg chem The amount of gains: 50,000 dollars in annual labor savings, 70 % improvement In accuracy tracking, and 3 % enhancement In general efficiency.

-LSPS) using the Tradlinx API saw Customer retaining a 20 % jump.

Tradlinx also provides an undeniable financial investment. The pricing model depends on Master B/L, not the number of containers. For a shipping company 400 containers under 200 Master B/LS per month, the cost is accurate $ 540. Control the competing solutions anywhere 2500 dollars to 6,250 dollars For the same sound –The difference of 5x to 12X makes the return on investment intuitive.

Strong technology, radically simple

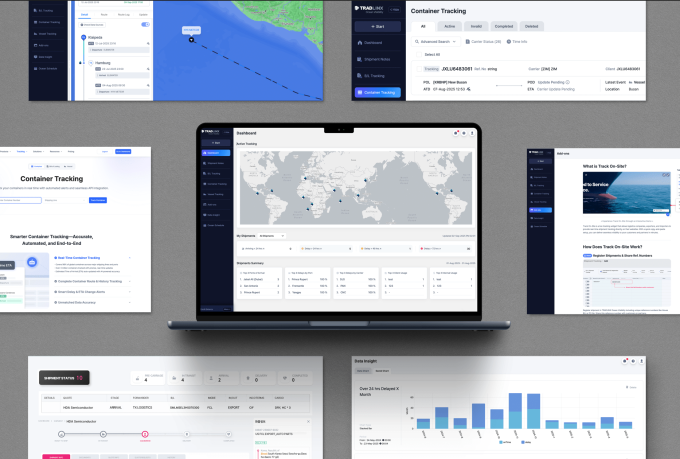

Tradlinx works primarily: technology should be easy to adopt. Its tracking component allows any company to add a vision in an actual time to its website Five minutes with no coding required.

For deeper integration, the strong applications programming interface is smoothly with FMS, TMS or existing systems, and destroying internal data silos. with Unlimited application programming interface requestsSystem domains with business growth. This approach to the leading accuracy is connected with practical use, and ensuring that everyone-from the interior to customers-deals with the same reliable data.

The new competitive standard

In the natural scene today, the victory is no longer specified by the range, but according to the quality of your data. Tradlinx’s success provides a plan for a new era of logistical services based on a comprehensive environmental system that collects, provides and provides reliable information. The standard of success is no longer just moving the goods – it is moving with certainty.

In -depth analysis: a comparative view of the leading solutions

Tradlinx recently published SCM Vision Investment Return 2025-2026‘ Report, direct comparative analysis of the leading vision solutions in the market. The report holds six main platforms, including Project44 and Fourkites, through three basic measures –The total cost of ownership (TCO), data reliability and operational efficiencyProviding a clear working framework for companies to determine the optimal solution. The full report is available on Tradlinx.