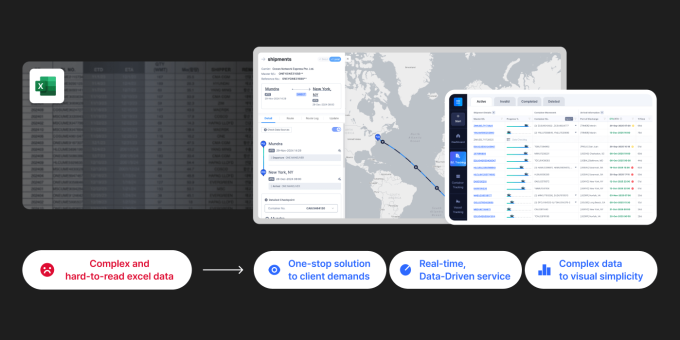

While artificial intelligence and robotics are transforming logistics, much of the multi-trillion-dollar shipping industry still relies on spreadsheets designed in the 1980s. This “digital divide” has become a major operational risk: a single typo or missed update can ripple through global supply chains, causing costly delays and eroding customer confidence.

High cost of manual tracking

Logistics professionals often start their day by manually updating spreadsheets with data pulled from multiple carrier websites, a time-consuming procedure that creates bottlenecks across operations.

Fragmented information: Managing hundreds of containers linked to multiple Master Bills of Lading (MBLs) across different websites in inconsistent formats creates operational chaos.

Poor data accuracy: Repeated manual entry is a major source of error, directly causing shipping delays and damaging customer confidence.

Growth barriers: A customer case study found that tracking just 10 shipments can take two to three hours each day, making scaling operations without adding staff economically impractical.

Ultimately, teams spend valuable time chasing merchandise instead of focusing on higher-value work, and companies bear the cost of inefficiency.

TRADLINX Dashboard: Real-time central control tower

TRADLINX’s integrated dashboard solves these challenges by consolidating all shipping data into a single monitoring tower, providing a single source of truth.

Key platform benefits include:

Easily integrate data: Pasting MBL numbers into your dashboard is all it takes to automatically merge data from multiple carriers in 10 seconds.

High update frequency and reliability: The platform automatically updates carrier data every hour or two, ensuring users have access to real-time information without manual intervention. The dashboard clearly displays ETA and changes color at ATA for confirmation at a glance.

Proactive risk management: The system automatically flags delays with color-coded alerts based on severity – yellow (>24 hours), orange (>2 days), and red (>4 days) – enabling teams to respond proactively. An optional Track Log feature, with a 30-minute update frequency, provides precise vessel positions when carrier data is scarce.

Reports and active participation: A comprehensive Daily Report can be generated with one click and automatically emailed to clients. Stakeholders can also be given a “share link” to view a real-time map of their shipments, increasing transparency.

From operational efficiency to strategic assets

Adopting a digital platform changes how a company makes decisions and accelerates growth. The TRADLINX dashboard provides visual analytics on delay trends by country and month, providing valuable insights for annual planning and carrier performance reviews.

The platform is designed on a large scale. Businesses that handle more than 500 shipments per month can use the TRADLINX API to integrate all functionality directly into their existing ERP systems. One employee who used to handle 10 shipments in two to three hours can now manage 100 shipments at the same time. The time saved – typically 20-40% of manual hours – can be reinvested in customer service and new business development.

This capability is delivered through a transparent pricing model starting at $3 per container per month, with no additional fees for multiple containers within a single bulk storage container, which significantly reduces the cost of tracking per container.

Digitization: the new standard in logistics

In today’s environment of constant supply chain uncertainty, relying on analogue methods is no longer viable. An integrated digital management system is now essential for achieving flexibility, efficiency and long-term competitiveness. Companies that effectively leverage real-time data will be better positioned to handle market fluctuations and achieve sustainable growth.